FAQ

No, EVA GLORY is aiming to promote the use of non-food crops (second and third-generation feedstock), such as cellulose, for the production of biobased materials. Innovative technologies are focusing on non-edible by-products of the production of food crops (agricultural wastes), which generates large amounts of cellulosic by-products such as rice husks, bamboo and wood residues that can be used to produce biopolymers.

Our H Series contents the usage of tapioca starch derived from cassava where they are grown and imported from Thailand. The paper industries are known for using industrial-grade starch in their products for more than decades, and the starch is not eligible for human consumption, thus the impact on food production is insignificant.

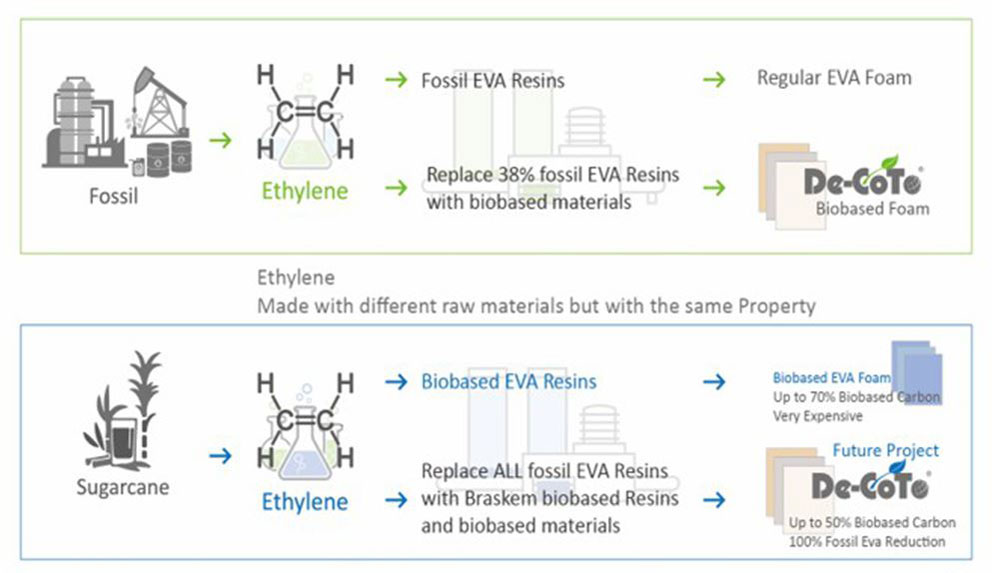

Bio-based materials can help to reduce the dependency on limited fossil resources, which are expected to become significantly more expensive in the coming decades. Bio-based materials are made from renewable sources instead of oil and that way gradually substitute fossil resources used to produce plastics with renewable resources (currently predominantly annual crops, such as corn and sugar beet, or perennial cultures, such as cassava and sugar cane).

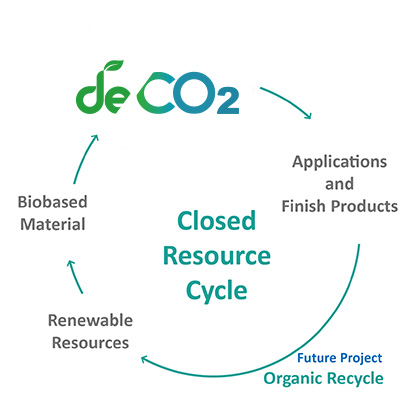

Biobased materials also have the unique potential to reduce greenhouse gas emissions or even be carbon neutral. Plants absorb atmospheric carbon dioxide as they grow. Using plants (i.e. biomass) to produce biobased material constitutes a temporary removal of greenhouse gases (CO2) from the atmosphere.

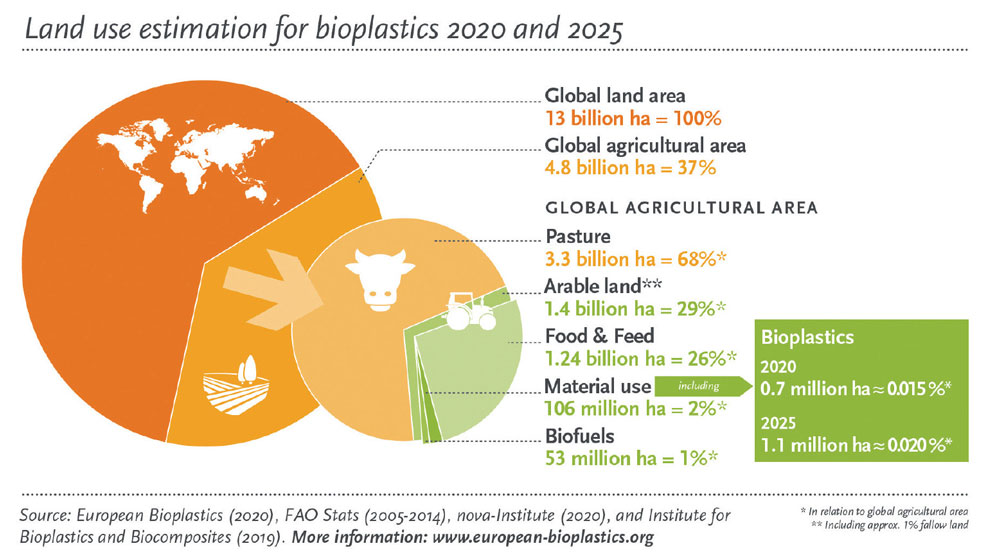

It is around 0.02% of the global land area in 2020. Today, bioplastics are mostly made from carbohydrate-rich plants, such as corn or sugar cane, so-called agro-based feedstock or 1st generation feedstock. Currently, 1st generation feedstock is the most efficient feedstock for the production of bioplastics as it requires the least amount of land to grow on and produces the highest yields. The feedstock currently used for the production of bioplastics relies on only about 0.02 percent of the global agricultural area – compared to 94 percent of the area, which is used for the production of food and feed. Despite the predicted continued growth in the bioplastics market at the current stage of technological development, the share of 13 global agricultural area used to grow feedstock for the production of bioplastics will remain around 0.02 percent in 2025.

This clearly demonstrates that there is no competition between food/feed and industrial production. A recent report by Wageningen Food & Biobased Research (Bio-based and biodegradable plastics – Facts and figures, 2017) calculates that “even if we would base all present worldwide fossil plastics production on biomass as feedstock instead, the demand for feedstock would be in order of 5 percent of the total amount of biomass produced and harvested each year”. Yet, such scenario is unlikely to happen since the bioplastics industry is also looking into the use of non-food crops (lignocellulosic feedstock), such as wood, straw, as well as waste products and side streams of the agro-industry for the production of bioplastics. Using an increased share of food residues, non-food crops or cellulosic biomass could lead to even less land needed for bioplastics than the numbers given above.

- Rice husks – Taiwan

- Wood – Taiwan

- Bamboo – Taiwan and China

No, it is possible to research which types of GMOs are approved for commercial cultivation, which is currently restricted to cotton, corn, and soybean only.